Latest News

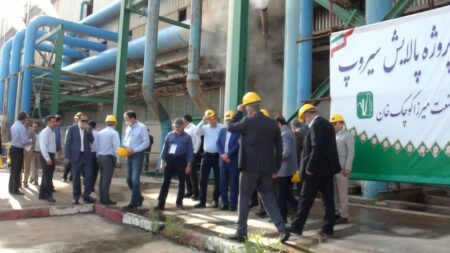

The indigenous “Sugarcane Syrup Refining” machine was put into operation / Dr. Naseri: production growth in the Sugarcane industry will be realized

By using the domestic “sugarcane syrup refining” machine in the second week of spring, the sugarcane industry took a big step in fulfilling the pronouncement of the year and from the very beginning, it brought “production growth” and “economic transformation” to Iran’s sugarcane land.

According to the PR report of Sugarcane & By-Products Development company, increasing production, improving the sugar quality and the enhancement of production process are the three distinctive features of this local machine, which the CEO of Sugarcane & By-Products Development company emphasized on during the commissioning ceremony.

Continuing the knowledge-based path for production growth

Dr. Abd Ali Naseri considered the design and construction of the sugarcane syrup refining machine by sugarcane experts to be the continuation of the knowledge-based path of the sugarcane industry, which started last year and its continuation in the new year will lead to the growth of production and economic transformation.

According to this report, the design and construction stages of this machine have been completed in the year of knowledge-based production, and after the completion stages and preliminary tests, it was put into operation in April this year.

Efforts of Sugarcane experts in the path of Resistance Economy

The CEO of Sugarcane Development praised the ingenuity and dedication of Sugarcane industry experts in manufacturing and localizing devices, industrial parts and agricultural machinery and called it a reliable support for passing sanctions and moving in the path of resistance economy.

Previously, the technology of making sugarcane syrup refining machine was monopolized by European countries, and with its localization by sugarcane experts, an important step has been taken in saving foreign exchange.

More extraction of sugar with the refining device

Naseri further mentioned the features of the sugarcane syrup refining machine and said that this machine significantly increases the quality of the sugarcane syrup obtained from the mill of the sugar factory and plays a significant role in the process of sugar production, further extraction and improvement of its quality.

Reducing the turbidity of sugarcane syrup, improving the performance of the cooking process and production are other important advantages of the sugarcane experts’ manufacturing machine, which was pointed out by the CEO of the sugarcane development company.

Cooperation of knowledge bases to improve productivity

In the continuation of this ceremony, the Managing Director of Mirza Koch Khan Agro-Industry, while referring to the process of designing and manufacturing this machine, said that in order to increase the quality of the extracted syrup for better use in the sugar cooker, since last year, studies of the syrup refining project by the specialists of this company and accompanying Knowledge-based companies were started and today, after less than a year, the project was put into operation.

Seyyed Hassan Mousavi added that all the parts of the refining machine were made by domestic knowledge-based companies, and its installation and commissioning project was carried out by domestic experts in a period of five months.

According to him, the use of domestic capacities in this project has brought currency savings and the cost of the refining device is significantly lower than the cost of buying it from foreign countries.

In the end, CEO of Mirza Koch Khan Agro-Industry, said that with the use of the sugarcane syrup refining machine, sugar production will be significantly improved in terms of quality and quantity.

Reducing waste and increasing production efficiency

In the opening ceremony, the industrial V.P. of Mirza Koch Khan Agro-Industry, while giving explanations, discussed the dimensions of project implementation, studies, the method of making the device and also its implementation.

Referring to the role of the refining machine in the production of high-quality sugar, Khaled Lowaymi added that the implementation of the mentioned project, in addition to having a high impact on the quality of sugarcane syrup for cooking, is also effective in production efficiency, improving quality and quantity, as well as reducing product waste.